Date posted:

Automation is an essential part of modern manufacturing facilities. Without machinery to help us, we wouldn’t have the accuracy or efficiency that we enjoy today. When our machinery breaks down, it’s more than an inconvenience – valuable time and loss of production can lead to missing a customer’s delivery. Disappointing…

Date posted:

MCI was contacted by a well known local meat processing company who had suffered a breakdown and loss of production. We quickly carried out some fault finding on the machine and found that metal particles had got into the hydraulic system damaging numerous components and valves. MCI’s engineers removed and…

Date posted:

MCI were called to a well known bakery, to investigate a problem with a Hypermill ultrasonic cutting machine. The fault was in one of the two generators which provide ultrasonic vibrations to the cutting blades. The generator was transferred to our workshop, where we found a faulty relay and a…

Date posted:

MCI received a meat slicer with a fault from a food manufacturer. Our engineers set to work to find out what was wrong and discovered that the inverter drive had failed. We replaced the drive, and the meat slicer was back in action. Another happy customer! If you are having…

Date posted:

MCI was called in by another new customer with a faulty control panel. The machine was out of action and, as a result, food production had halted. No product means no income, so (of course) it was critical to the customer. MCI removed a faulty HMI panel and diagnosed major…

Date posted:

MCI received a request from a food supplier who wanted a safety system fitted to their automated fryer. MCI designed, manufactured and installed a system based around the customer’s requirements. This system works with the existing machine sensors, to shut the machine down if there is an issue. If you…

Date posted:

MCI was called out to look at a customer’s pastry making machine. Production had halted – no sausage rolls or steak bakes. Our engineer found the cause of the error and quickly went to work and repaired the machine in good time. The pastry machine was back producing savoury pastries…

Date posted:

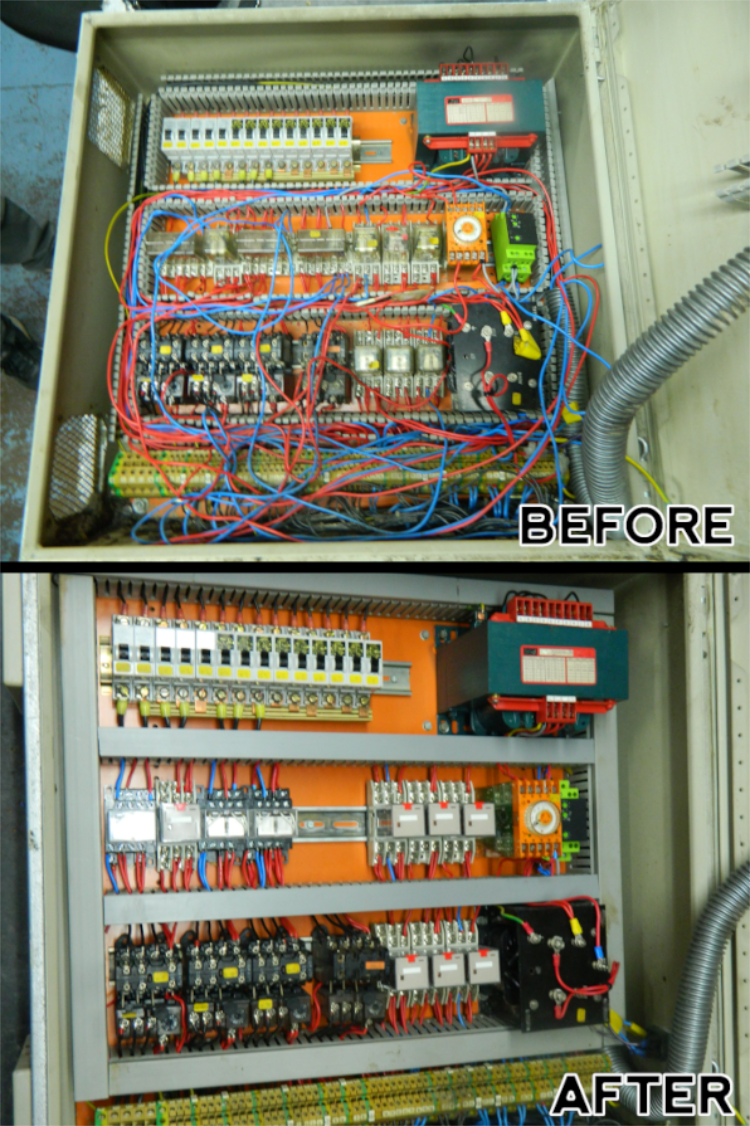

MCI received this machine control panel from a food manufacturer. Our engineers saw that faulty relays and bases were preventing the machine from running properly. The job was urgent due to production demand, so we turned the repair around in less than a week for the customer. As you can…

Date posted:

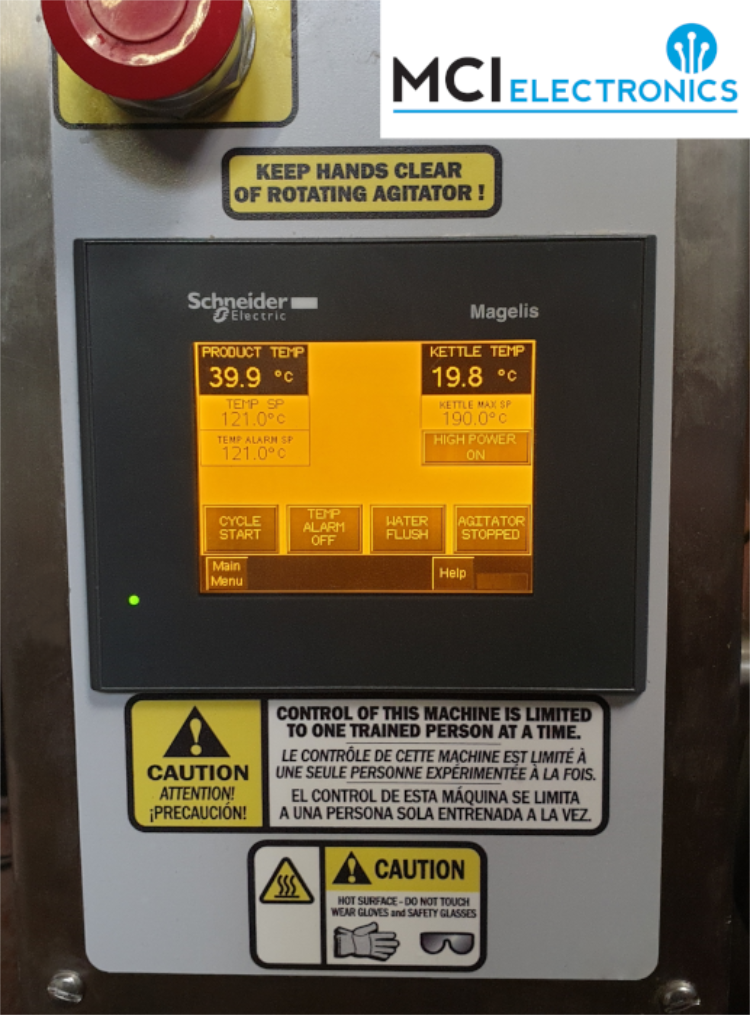

The new client to MCI sent in a faulty industrial mixer. MCI’s repair team traced the fault to a damaged probe unit built into the control panel. MCI repaired, tested, and returned the unit back to a happy customer. If you are having control unit problems, just give us a…

Date posted:

MCI received this industrial catering machine. The only information that we got from the customer was that it wasn’t working. When our engineers took the machine apart, they discovered that years of grease and grime had seeped into the machine, contaminating the circuit boards and components. After a good clean,…