Date posted:

MCI received an urgent call from a local confectionery company which was part of a larger national group of companies. An essential piece of equipment, a metal detector, had stopped working and production was set to be severely compromised if MCI couldn’t get the machine working again. An engineer had been…

Date posted:

MCI were asked to attend a custom door manufacturer’s factory to repair an edge banding machine that had failed. On arrival, we found that the PLC had failed, with no power and no lights illuminated. Because of the age of the machine, the PLC was obsolete – but for MCI,…

Date posted:

Every workplace has a machine that has been there from the beginning, your workhorse and old faithful that you always rely on. It may have been there as long as you can remember, or (in the case of some of our customers) for generations. When it breaks down, production may…

Date posted:

MCI were called out to an emergency at a bottling plant. A Krones Prontomatic bottler / labelling machine had conveyor issues halting production. MCI’s engineers investigated and diagnosed a fault on a profibus card fitted to one of the obsolete Danfoss drives. The drive was removed and taken to our…

Date posted:

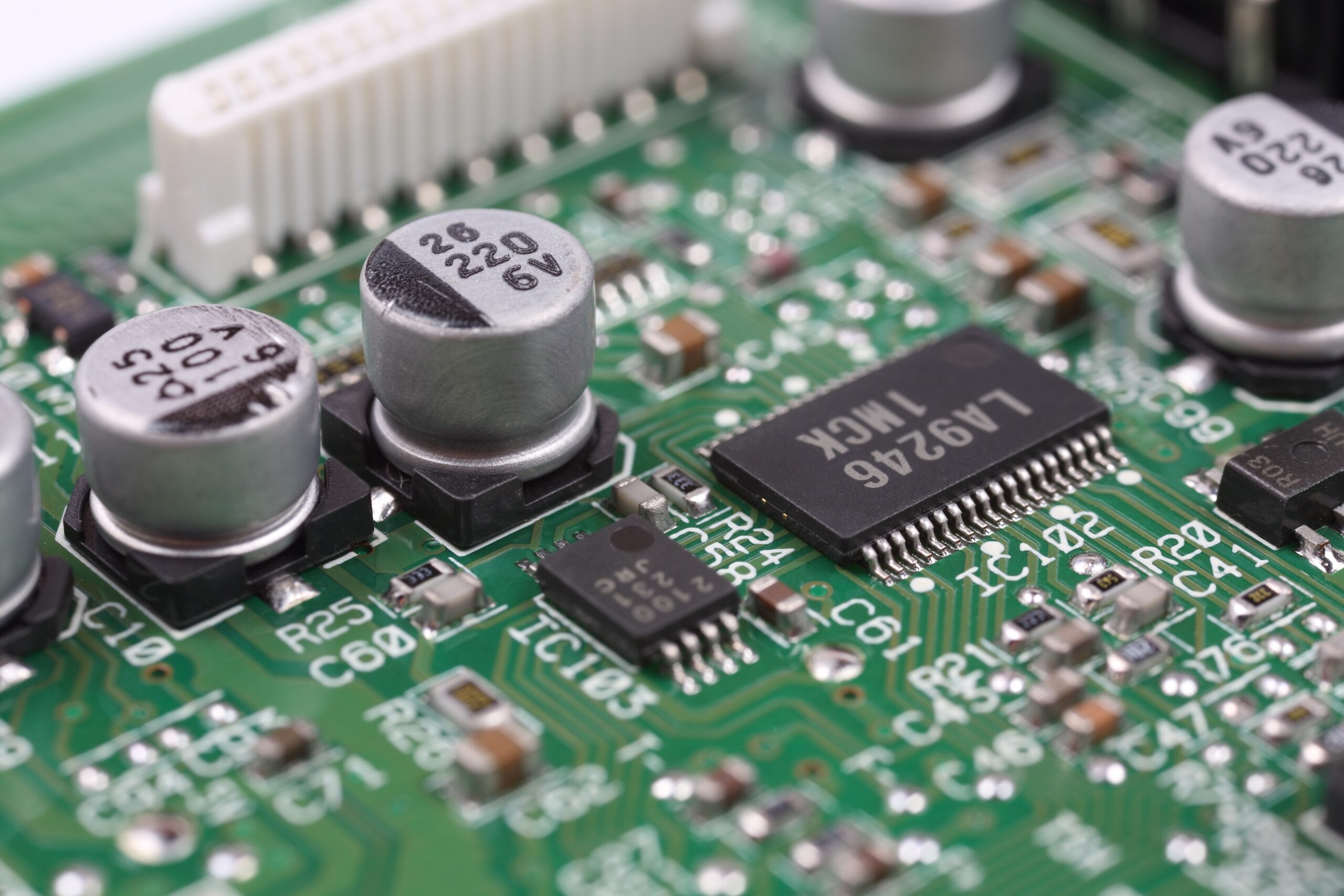

This post is a follow on from our post on 24th June 2024. A well known football team asked MCI to redesign and produce obsolete printed circuit boards to control their turnstile operation. MCI designed, modernised and built the control boards. We also returned to the football stadium to fit…

Date posted:

MCI were asked by a well known football team to produce some printed circuit boards to control their turnstile operation. The club couldn’t just purchase new boards as the boards were deemed obsolete. This didn’t stop MCI from helping. From an old sample, MCI designed, modernised and produced the PCBs…

Date posted:

MCI were asked to attend the site of a customer, who makes over 60 million paper bags a week per week. That’s a lot of hard working machines! Their industrial printer had problems with speed control and tension. The machine control was a trusted workhorse which had served the customer…

Date posted:

MCI received a call from a new customer who manufactures portable cabins. Their long serving wood pressure treatment machine had a failed Mitsubishi PLC. Unfortunately, the customer did not have a backup of the PLC program, so it had been very difficult to get the machine running again without MCI’s…

Date posted:

A long standing MCI customer, who makes gas turbines for industry, civil and defence aerospace etc. had a broken spark erosion machine. This machine is used to cut vanes for turbines from very hard materials like titanium. Traditionally, a milling machine would be used to cut materials, but because the…

Date posted:

Following an obsolescence audit at a customer’s facility, an expensive upgrade was recommended by the machine manufacturer which would result in loss of production for some time. As a more cost effective solution, MCI was asked to keep the original machinery going by sourcing three obsolete drives. Not only would…