Date posted:

MCI received an ECU for a well known German vehicle. Once our engineers had cleaned the circuit board up, we were able to diagnose and replace a faulty inductor coil. Another happy customer. If you are having electrical or electronic problems with your vehicles, give MCI a call on 01324…

Date posted:

MCI got an interesting repair in recently. The boom operation from a Horizon crane (that any self respecting child would want in their toy truck collection) had broken down. Our engineers did some fault finding and discovered some faults on the components in the main control panel. The components were…

Date posted:

MCI was called in by another new customer with a faulty control panel. The machine was out of action and, as a result, food production had halted. No product means no income, so (of course) it was critical to the customer. MCI removed a faulty HMI panel and diagnosed major…

Date posted:

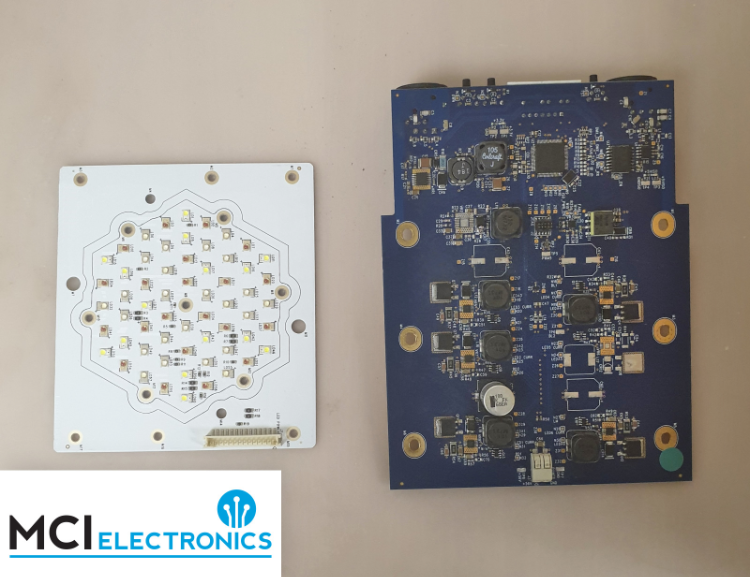

MCI received some troubadours (stage spotlights) from a new customer. We were told that they had stopped working after having an electrical spike. Upon examination, we found that the main control board for the troubadours was blown and they were beyond economical repair. We managed to source replacement parts from…

Date posted:

One of MCI’s long standing customers had an issue with a 1960’s packaging machine. The machine was not completing its sequence and stopping production. After our engineers had investigated it’s old relay logic control, they found that one of the sensors wasn’t signalling to the control relays. After replacing the sensor…

Date posted:

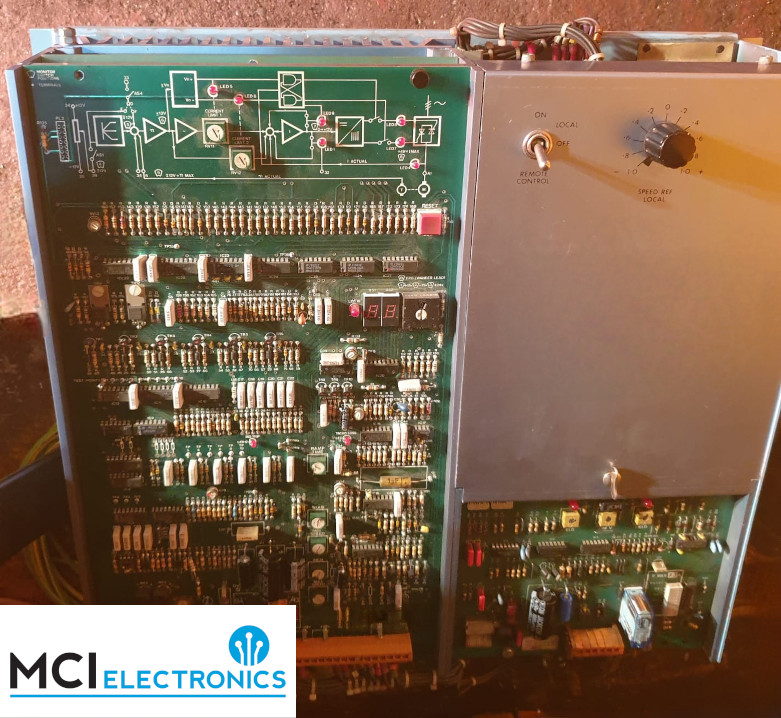

Another new client has come to MCI Electronics to ask them to look at a ‘dead’ Thyristor speed control drive for a lathe. Our engineers set to work fault finding the obsolete control unit and found multiple faults. After replacing all of the main power components, the panel was tested…

Date posted:

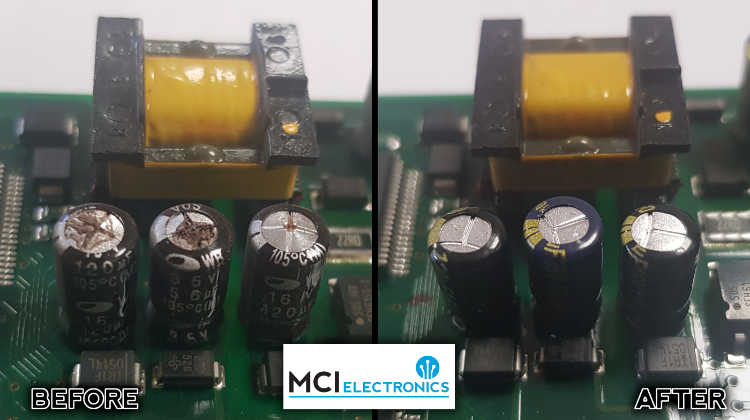

MCI received a Siemens Micromaster communications module from a pharmaceutical distributor. After our engineers had a look, they found that the capacitors had failed. After removing and replacing them, the module was back in action. Another happy customer! MCI is proud to work for many companies across the UK and…

Date posted:

MCI has received this testimonial from another happy new customer: “My boat …[is] an 11metre steel Dutch Schooner. I sailed home to Glencoe from Friesland in 2018…using the ST7000 Autohelm continuously after leaving the Dutch canals…[and, during that time,] it failed on passage to Rathlin Island… I struggled to isolate…

Date posted:

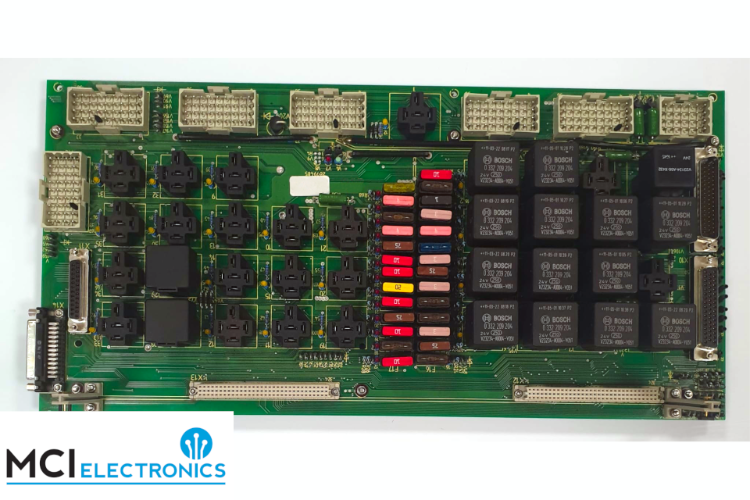

MCI received a control board for a Unimog Railtrack vehicle. We set to work fault-finding and discovered damaged tracks and relays. It was soon repaired and returned to the customer. If you are having any electrical or electronic problems with your vehicle, give MCI a call on 01324 611371 to…

Date posted:

MCI received a call from a new customer whose printing machine had a servo drive and motor going into fault. We carried out an onsite visit to determine the fault and connected our laptop to the drive. We then found that the drive parameters were incorrect and, once we modified…