Date posted:

MCI were approached by a major worldwide air conditioning company to repair a circuit board from their test equipment, used to ensure the air conditioning units pass their quality process before dispatch. The hand made circuit board came from a bespoke testing machine. The board needed to be fully realised…

Date posted:

MCI received an urgent call from a local confectionery company which was part of a larger national group of companies. An essential piece of equipment, a metal detector, had stopped working and production was set to be severely compromised if MCI couldn’t get the machine working again. An engineer had been…

Date posted:

MCI received an emergency repair from a nationally renowned bakery. A chocolate extrusion machine had broken down. No chocolate extrusion machine, no lovely chocolatey delights. MCI wasn’t just helping the bakery, it was almost performing a public service! Time was definitely of the essence with this repair. MCI’s engineers came…

Date posted:

MCI received a B&R Touch screen Automation PC from a large International fresh produce supplier. The system failed to power up and this caused the production line to be down. Needless to say at this time of year the customer was desperate and needed this to be fixed as a…

Date posted:

MCI was contacted by a well known local meat processing company who had suffered a breakdown and loss of production. We quickly carried out some fault finding on the machine and found that metal particles had got into the hydraulic system damaging numerous components and valves. MCI’s engineers removed and…

Date posted:

MCI were called out to an emergency at a bottling plant. A Krones Prontomatic bottler / labelling machine had conveyor issues halting production. MCI’s engineers investigated and diagnosed a fault on a profibus card fitted to one of the obsolete Danfoss drives. The drive was removed and taken to our…

Date posted:

MCI were asked to attend the site of a customer, who makes over 60 million paper bags a week per week. That’s a lot of hard working machines! Their industrial printer had problems with speed control and tension. The machine control was a trusted workhorse which had served the customer…

Date posted:

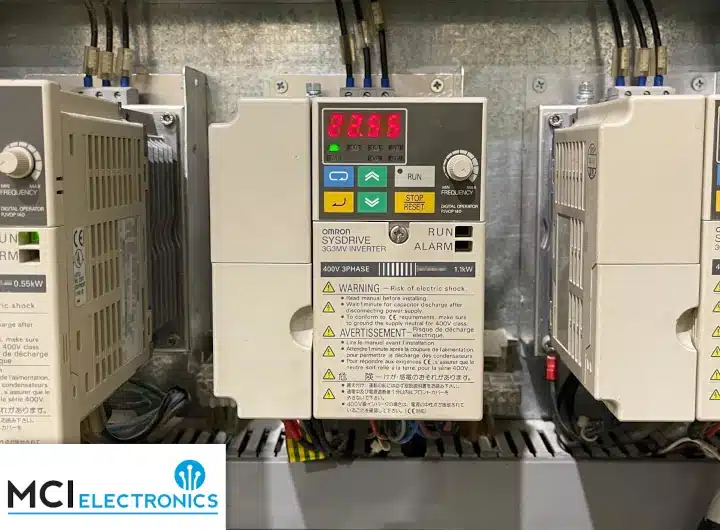

MCI was asked, by a manufacturer, to fix their main production machine. The old inverter had failed and the customer didn’t have a backup to programme the settings on the new inverter. MCI came to the rescue and were able to bring the old inverter back to life just long…

Date posted:

Following an obsolescence audit at a customer’s facility, an expensive upgrade was recommended by the machine manufacturer which would result in loss of production for some time. As a more cost effective solution, MCI was asked to keep the original machinery going by sourcing three obsolete drives. Not only would…

Date posted:

MCI was called in by another new customer with a faulty control panel. The machine was out of action and, as a result, food production had halted. No product means no income, so (of course) it was critical to the customer. MCI removed a faulty HMI panel and diagnosed major…